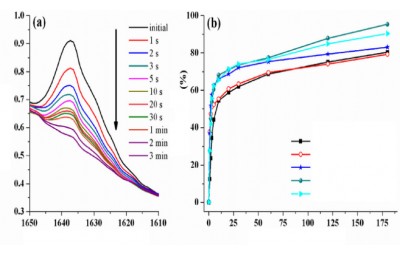

#FTIR

#DMA

Do you determine the content of a certain monomer in a polymer by FTIR or by DMA? Do you see a relationship between those two techniques and does it help to improve your determination?

Join this exclusive training on Thursday, 15th Feb 2018 and get new ideas for analysing materials by combining FTIR and DMA. It will give you appetite to approach difficult analysing problems with a combination of techniques which can be used to assist with faster product developments…

#DMA

Do you determine the content of a certain monomer in a polymer by FTIR or by DMA? Do you see a relationship between those two techniques and does it help to improve your determination?

Join this exclusive training on Thursday, 15th Feb 2018 and get new ideas for analysing materials by combining FTIR and DMA. It will give you appetite to approach difficult analysing problems with a combination of techniques which can be used to assist with faster product developments…

REGISTER HERE: https://onlytrainings.com/FTIR-DMA-combined-study-for-quick-analysis-and-fast-product-developments